EXTRUSION TECH

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to EXTRUSION TECH

Single Shaft Shredder

OPERATION:Single shaft shredder operates on heterogeneous medium hard material by impact, cut and brake process.

The shredding process works on rotor-stator device, material are fed in the hopper from where is dropped in the shredding chamber.

Following machine start, material is put ahead by plate moved by hydraulic pusher which pushes them against rotor

This kind of configuration allows to shred even big pieces, which stay in shredding compartment up to reach right dimensions to be throughout from the screen

Rotor shaft is driven by electric motor connected with a gear box. The bottom part of shredder is closed by screen grid .Shredded material dimensions can be pre selected by screen assembling

Single shaft shredder is suitable for reducing size of wide range of plastic material like purging / lump, profiles, films, heavy wall thickness pipes, plastic molding etc

Hydraulic Screen Changer

Features & Benefits

Manufactured from high grade tool steel

Maximum surface area

Two detachable breaker plates

Cartridge heaters and thermocouple for temperature control

Low maintenance design

Torpedo fitted inside screen changer for easy start up

Special quality Teflon and brass seal

Lever Type Manual Screen Changers.

Description / Specification of Lever Type Manual Screen Changers.

We are involved in offering a wide range of Lever Type Manual Screen Changers. to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Lever Type Manual Screen Changers.. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Lamination Die With Internal Deckling

Description / Specification of Lamination Die With Internal Deckling

We are involved in offering a wide range of Lamination Die With Internal Deckling to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Lamination Die With Internal Deckling. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Choker Bar Die For Thermoforming

The die machined from special high-grade alloy steel.

All Flow surfaces in contact with the polymer are high grade polished and hard chrome plated. The exterior surfaces are flash chromed

UPPER LIP:Flexible@emspLOWER LIP:Adjustable.

LIP OPENING:Minimum: 0.3mm to Maximum 5mm

Hand adjustment by push screws M12 X 80 Acting on the Flexible Lip.

Manufactured from high grade tool steel

Maximum surface area

Two detachable breaker plates

Cartridge heaters and thermocouple for temperature control

Low maintenance design

Torpedo fitted inside screen cha

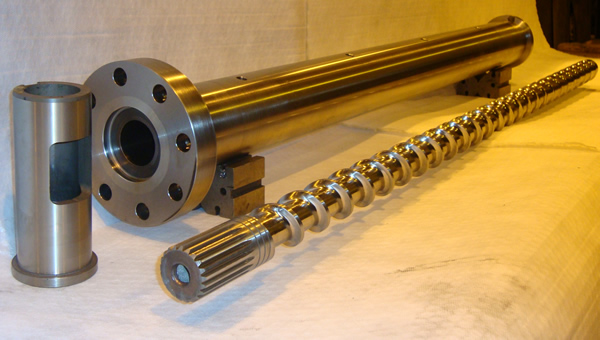

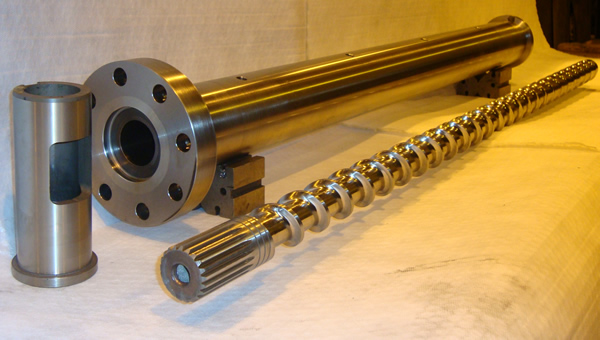

Screw And Barrel

We have different designs of screw and barrel with grooved feed for extruder or injection to meet customer's demand.our factory manufactures with high-quality material, applying the method of hardening and tempering and nitriding, thus it enjoys the characteristics of long working life, wear resistance, and anti corrosion. Besides, the technique of hard alloy spraying or chrome plating can be used on the working surface of screw, which will make it have better using effectiveness.

Grinders

Description / Specification of Grinders

We are involved in offering a wide range of Grinders to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Grinders. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.